Abstract

[Introduction]

Chimeric antigen receptor T (CAR-T) cell therapy targeting CD19 has shown good outcomes in patients with relapsed or refractory (r/r) B-cell malignancies, and the number of patients awaiting this therapy is increasing dramatically. Successful CAR-T cell therapy can be achieved only after a number of steps are optimized. Of these, it is essential to ensure that CAR-T cells are manufactured without failure. Although manufacturing failure rates range from 1 to 13%, its causes and risk factors remain unclear. Therefore, we sought to determine risk factors for CAR-T cell manufacturing failure in a real-world setting.

[Methods]

This retrospective study, conducted by the Japan Society of Transfusion Medicine and Cell Therapy, enrolled patients who underwent CAR-T cell production for tisagenlecleucel (tisa-cel) using T cells harvested at 23 Japanese institutions from October 2019 to March 2022. Clinical factors, including patient characteristics, laboratory tests at apheresis, and apheresis procedures, were compared between successful and unsuccessful case groups. Categorical and continuous variables were compared between groups using Fisher's exact test and two-tailed unpaired Student's t-test, respectively. In comparison between groups, CD4/CD8 ratio was log-transformed to normalize skewed distribution. We evaluated the effect of each factor on the manufacturing outcome using a logistic regression model. p values <0.05 were considered statistically significant.

[Results]

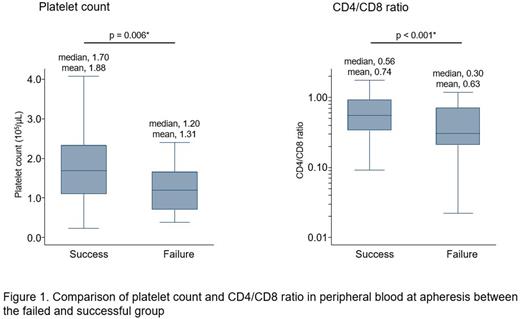

We analyzed 519 cases, including 438 diffuse large B-cell lymphoma (DLBCL) and 81 B-cell acute lymphoblastic leukemia (B-ALL) cases. Whereas no manufacturing failure was observed among B-ALL cases, there were 30 manufacturing failures (6.8%) among DLBCL cases. Then, we compared clinical factors between DLBCL cases that failed (n = 30) and that succeeded (n = 378), excluding those employed in clinical trials for out-of-spec products. The number of chemotherapy cycles performed prior to apheresis (median 13 vs. 10; p = 0.01) and the proportion of patients with previously treated with 3 or more cycles of bendamustine (43.3 vs. 10.9%; p < 0.01) were significantly higher in the failed group than the successful group. Regarding cell counts in peripheral blood at apheresis, platelet count (1.20 vs. 1.70 × 105/μL; p = 0.01) and CD4/CD8 ratio (0.30 vs. 0.56; p < 0.01) were significantly lower in the failed group than the successful group (Figure 1). For T-cell collection, Spectra Optia® was used in 403 cases (98.8%), and there were no significant differences in the failure rate in terms of the device type or collection program. There were no significant differences in the total number of CD3+ cells (3.1 vs. 2.9 ×109; p = 0.51) or proportion of CD3+ cells to total nucleated cells (55.6 vs. 46.4%; p = 0.14) shipped for tisa-cel production between the failed and successful groups. Multivariate logistic analysis revealed that history of 3 or more cycles of bendamustine therapy prior to apheresis (odds ratio [OR], 3.19; 95% confidence interval [CI], 1.04-9.82; p = 0.04), low platelet counts (OR, 0.52 per 105/μL; 95% CI, 0.28-0.96; p = 0.04), and low CD4/CD8ratio (less than one third) (OR, 3.06; 95% CI 1.23-7.59; p = 0.02) in peripheral blood at apheresis were risk factors for CAR-T manufacturing failure.

[Conclusions]

This study showed that manufacturing failure remains an obstacle to CAR-T cell therapy. Repeated use of bendamustine prior to apheresis, low platelet counts, and low CD4/CD8 ratio in peripheral blood at apheresis were associated with increased risk of manufacturing failure. Avoiding these risk factors before apheresis and risk-adopted therapeutic strategy after apheresis may help to optimize CAR-T cell therapy for patients with r/r B-cell malignancies.

Disclosures

Jo:Nippon Shinyaku Co., Ltd.: Research Funding. Ri:Janssen Pharmaceutical: Honoraria; Bristol-Myers Squibb: Honoraria, Research Funding; Celgene: Honoraria, Research Funding; Daiichi Sankyo: Research Funding.

Author notes

Asterisk with author names denotes non-ASH members.

This feature is available to Subscribers Only

Sign In or Create an Account Close Modal